Paul Blackman has used business and manufacturing processes over many years. He shares his insights of using Kanban for any business type

"Those who know me; also know I am a “Lean” advocate and have been for a number of years. Why? - Because it works on so many levels whatever business you run" PB

Take the well-known manufacturing Kanban process for example. “KAN-BAN” meaning Kan - Visual and Ban - card

This is my ‘go to’ method; when reducing Turn-around Time (TAT) inventory and increasing process effectiveness (PE).

Before we move into discussing “Kanban process” I’ve identified some of the key benefits which I believe are the key to implementation and something I use on a regular basis when supporting our clients:

- It is a ‘Pull’ system so is triggered by demand and is highly effective at helping balance flow through any process.

- It is owned by the users. It increases team engagement and as a visual system requires minimum training. Therefore, it is quick to implement and explain.

- It is easy to extend as it is as relevant inside the producing business as it is in the supply business. Often Kanban is linked to planning and costing models. I will cover this a little further on.

- It has very low cost of entry - as it can be created with internal parts or using specifically designed containers and labels etc.

- As a visual system it is not language dependant so is fully usable by groups of multiple languages or levels of ability.

- The ‘delivery’ or ‘position’ is extremely easy to confirm by walking and observing – it is therefore easy to manage problems and understand up stream or down stream implications.

How could it work in your business?

Firstly, it is imperative that as a logic process it requires key element consistency.

- These are Fixed quantity per card (plaque or other, representative item)

- Trigger replenishment point to avoid stock out failure

- Maximum amount in the Kanban

- The total TAT

- Your process work time

In terms of calculation you can make this extremely accurate or let true demand ‘improve’ the overall Kanban size.

I prefer to calculate the demand first then determine the input rate (upstream to down stream flow) then determine the ‘bucket and card size’ by the customer need (Takt time).

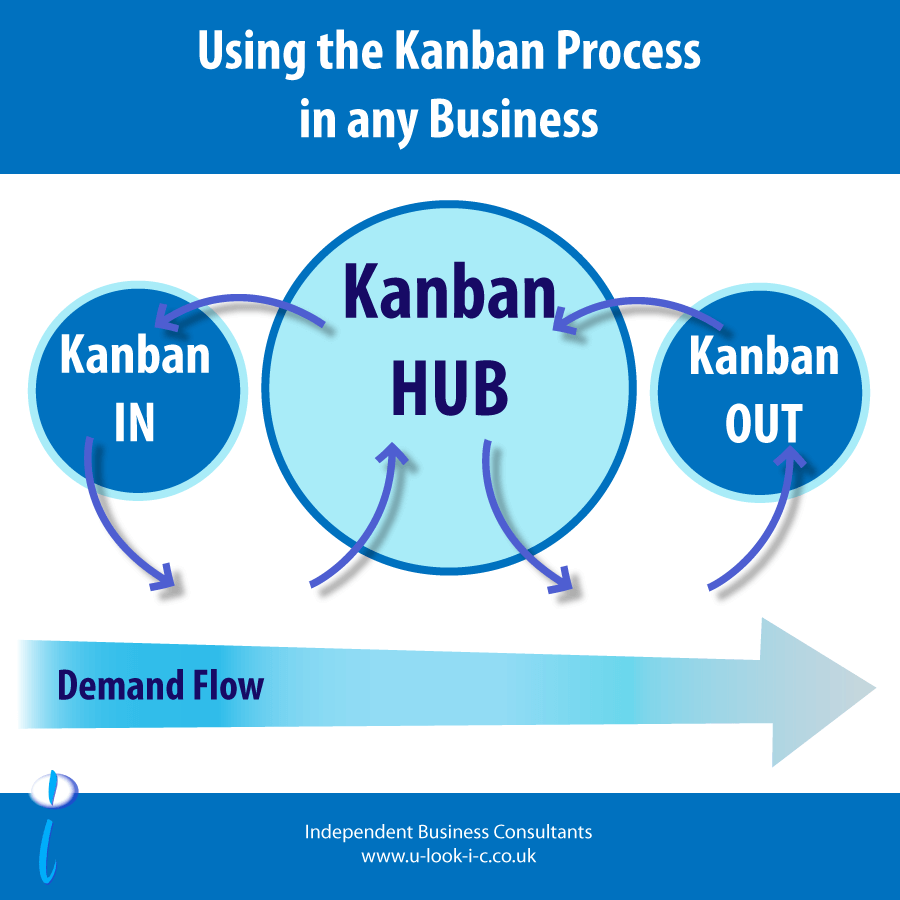

If we look at a simple visual to explain

As with any process; there are some rules

- Customer (downstream) processes by known demand, withdraw items in the precise amounts specified by the Kanban. This then ‘Pulls’ from:

- Supplier (upstream) who then produces items in the precise amounts set on the ‘card’ and transfers/creates demand in sequences specified by the Kanban.

- Kanban - No items are made or moved without a Kanban. This is essential or the validity and control is lost.

- Rejection - If items are rejected or amended through the

quality system then manual intervention is necessary to compensate.

- Defects and incorrect amounts are never sent to the next downstream process.

- A Kanban identifier should accompany each item, every time.

- Demand review - The number of Kanban’s is reduced carefully to lower inventories and to reveal problems. This can be careful calculation or by allowing the demand actual dictate as Kanbans that are over or understocked become easily apparent by visual examination.

No demand no trigger- so no consumption of parts / resource

Process Interaction

As this process interrelates into other business areas the process map of the business can be designed very easily from the pull of demand. I will expand.

Scenario

If a company has a material planning and purchasing system based on MRP or MPS approaches then the danger is that inventory can increase if not consumed as the plan. Therefore material (cost) is pushed into the process rather than pulled through by actual demand. My point is that MRP etc. is best used for planning and Kanban for control as the total demand (plan) cannot be exceeded as the Kanban structure is balancing flow.

If left unrestricted MRP can increase inventory due to unbalanced flow either by external to internal (stock in) or internal flow not matching total pull. Whereas Kanban; in conjunction “manages” the flow and allows for quick intervention allowing more CONTROL.

My findings when supporting business, a common point that can be missed, for many reasons, is the need to understand both true cost and Margin opportunities should be at the forefront of any business then Kanban is a perfect process to measure both activity and material consumption at set points of the process.

Data can be captured to a work station type cost model or real time cost if linked to the individual moves in Kanban. The principal point of measurement is to use the sequential moves in time to allocate cost. Therefore, a clear relationship between cost and flow and TAKT time change is established. The individual teams can understand cost and real effectiveness not only on an ‘efficiency’ point but as a modeller for Kaizen related decisions.

As the system requires limited Management intervention it can be managed at user level and as such the involved groups increase in useable (valuable) skills, contribute and become more effective. In real terms Kanban’s increase true value add and reduce waste.

Conclusion

My belief is that correct use of the Kanban process; can be used in many forms and is not just designed for manufacturing businesses. The advantages are both in engagement and financial. The reduction in inventory is an obvious attraction; but this must not dominate, as I believe the real wins are across the business, on many levels:

- Employee engagement

- Managing demand based on customer pull

- Margin uplift

- Visual and very much part of the demonstration of your business value proposition

- Real time cost.

- Low cost of implementation

- Inventory balancing

How do we help?

If you’d like to find out more about using the Kanban process or want have a conversation about how we can help your business give us a call

Paul Blackman

We help to change perceptions by assisting with improved working methods. We work to ‘align functions’ and increase your business ability and profitability.

…and most of all we are Independent Growth Consultants, on your side!

Contact us for a no obligation chat or to find out more gives us a call we’d love to hear from you